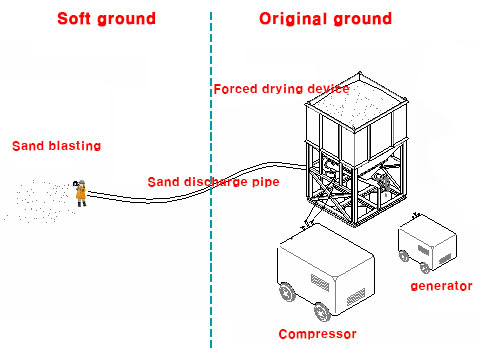

Forced dry sand placement

페이지 정보

본문

Horizontal drainage material installation in ground where equipment access is difficult

1. Overview of the method

When installing horizontal drainage material in extremely soft ground, high pressure air and pipes are used to enable even and easy installation in areas where equipment access is difficult, and the installation thickness can be freely adjusted to minimize uplift and destruction of the soft layer during installation.

2. Features of the method

1) Minimization of uplift by preventing concentrated load

① By adjusting the installation thickness and area (at least 10 cm per time), overpressure can be prevented and the flow of the soft layer can be minimized. 2) Easy to secure distance and area using drain pipe

① Easy to install and remove using lightweight Ø=150mm high pressure drain pipe (L=6~10m), and easy to adjust direct delivery distance (maximum 150m)

② Easy to secure installation area using corrugated pipe of high material with easy directionality for drain pipe (high pressure straight pipe) drain section

3) Sand laying in super soft layer

① Even in areas where manpower and equipment cannot be inserted after P.E, P.P MAT laying,

② Laying is possible using a crane (review specifications by laying distance). Even at this time, laying thickness and area can be adjusted.

4) Easy to install and remove equipment

① All parts except sand supply device can be disassembled, and lightweight and easy to transport.

② Sand supply device (standard amount 10.5㎥) can also be adjusted according to construction conditions.

③ Install rollers on the bottom of the supply device body for easy movement and direction change

5) Horizontal drainage material (sand) can be laid after 6 months from the dumping of dredged soil.

3. Construction method and order

1) Install forced dry sand laying device

2) Install sand transfer drainage pipe

3) Inject air and operate drainage motor

4) 1st laying (laying thickness that allows personnel to enter)

5) Extend or reduce drainage pipe

6) 2nd laying (laying thickness that allows wetland guides and clamshells to enter)

7) Move equipment and continuously perform 1) to 6) tasks