dynamic compaction

페이지 정보

본문

Free-fall ground improvement method

1. Method overview

This method improves the ground to the required depth by lifting it to the planned height (10 to 30 m) using a special device equipped with a heavy weight (Pounder) weighing 10 to 30 tons and then freely dropping it to apply impact energy to the ground. It can be applied to various soil types such as sand, silt, rock, garbage and waste landfill, and can be efficiently applied to the foundation ground treatment of building foundations, tank foundations, site development, railways, roads, and airport runways.

2. Method characteristics

1) The combination work of the site is relatively simple.

2) It can be applied to a wide range of soil types.

3) No special chemicals or materials are required.

4) The construction period is shortened compared to the other methods (piling, ground consolidation, etc.).

5) The construction cost is lower than that of the other methods.

6) There are restrictions due to noise and vibration in places where structures such as soil cores are densely packed.

7) Plan construction according to improvement conditions, not unplanned impact.

3. Construction method and order

1) Ground leveling and selection of test construction location.

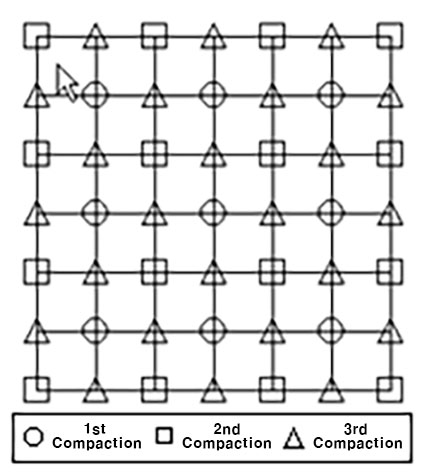

2) Measurement and marking of impact point.

3) Investigation before test construction (plate loading test).

4) Pilot compaction construction (Pilot Test).

5) Conduct test compaction (1st, 2nd, 3rd, final compaction).

6) Investigation after test construction.

7) Analysis of test construction results.

8) Conduct main compaction (1st, 2nd, 3rd, final compaction).

9) Investigation after main construction (plate loading test).

10) Results organization and analysis